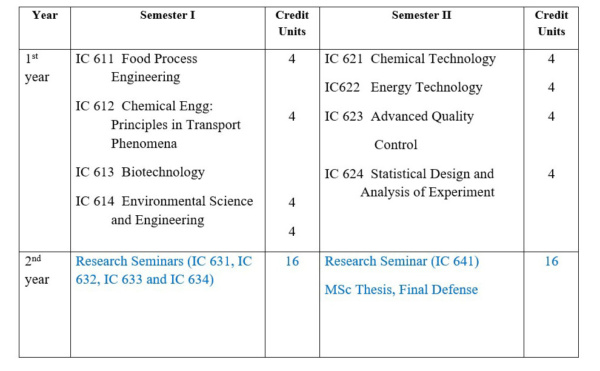

MSc

Courses in Master of Science (Two-year Program, Total Credit Units 64)

First Year MSc

Course Description

Food Process Engineering

This unit can provide the knowledge in the production of value-added fruits and vegetables related to agro-economics based on nutrition and food safety. Fats and oil technology and their physico-chemical properties are also included in this course.

Learning Outcomes

At the end of the course, the students must be able to:

-Understand keeping the nutritional quality of fruits and vegetables, good quality of fats and oil.

-Apply the knowledge in production of value added fruits and vegetables related agro-foods.

-Integrate the production techniques by maximizing the yield and quality.

-Identify the operations involved in food processing industries.

-Analyze and evaluate the problems involved in unit operations.

Chemical Engineering Principles in Transports Phenomena

This module gives the principles and concepts related to phase separation including distillation and absorption. It also connected with the mass and heat transport phenomena when considering reactor design.

Learning Outcomes

At the end of the course, the students must be able to:

-Understand the phase separation in distillation and absorption units.

-Design proper separation techniques and heat and mass rates.

-Analyze the phases and heat and mass balances.

Biotechnology

The course deals with the metabolic pathway of carbohydrates, fatty acids and amino acids. It also involves principles of fermentation, bioremediation and wastewater treatment.

Learning Outcomes

At the end of the course, the students must be able to:

-Understand advanced fermentation technology and various types of bioreactors.

-Understand the process layout of wastewater treatment.

-Understand the role of enzymes, their immobilization and productions.

-Understand about organic compounds and contaminants.

-Understand the Single-cell proteins and application of microorganisms in making foods.

Environmental Science and Engineering

Environmental Science and Engineering is the study of the principles of sustainable and green chemistry. Key topics are the characteristics of wastes from different industries and key concepts on waste disposal. It also illustrates the chemistry, toxicity, environmental fate and transport of twelve POPs.

Learning Outcomes

At the end of the course, the students must be able to:

-Understand the environmental and human toxicity of persistent organic pollutants.

-Understand the treatment methods of waste emerged from Industrial plant.

-Apply the systematic waste management system in chemical process industries.

-Identify the efficient methods of waste control in industrial plant.

-Illustrate the appropriate materials and methods used in control of environmental pollution problems.

Chemical Technology

This module focus on the production of ceramic, cement, glass, sugar and starch, pulp and paper, paint, varnish, lacquer and allied, leather, gelatin and glue products. It also covers the modern techniques for the preparation and applications of sulphur and nitrogen compounds.

Learning Outcomes

At the end of the course, the students must be able to:

-Understand the manufacturing process and quality control of sugar, starch and related products in sugar and starch industries.

-Understand the processing of paint, varnish, lacquer and allied in organic surface- coatings industries as well as processing, properties and uses of leather, gelatin and glue in leather and leather-tanning industries.

-Understand the fuel consumption in combustion of sulphur compounds, lime, cement and ceramic in chemical technology.

Energy Technology

This unit gives an overview of the current and future technology for deriving energy from biological resources. It also helps the students to understand both radiation and production of bioenergy and nuclear power.

Learning Outcomes

At the end of the course, the students must be able to:

-Apply the processing technology for the production of bioenergy and biofuel (bioethanol, biodiesel) as renewable energy.

-Understand the radiation sources, effects of radiation and how to dispose radioactive waste.

-Review nucleon fusion and nuclear fusion power technology for the generation of nuclear power.

-Classify and analyze the lubricant oil blends which are designed to perform several jobs in engines and other industrial machines.

Advanced Quality Control

This course describes evaluation and interpretation of analytical data which eliminates probable error for sampling processes. It also includes the study of the HPLC and the performance of electrophoresis and electro-chromatography in addition to dealing with the principles of instrumental technique and isolating the elements in compound as pure a form as possible form as possible.

Learning Outcomes

At the end of the course, the students must be able to:

-Manipulate the advance instrumentation of relevant terms of UV, IR, MS, NMR and AAS spectroscopy.

-Understand the instrumentation techniques and working principles of UV, IR, MS, NMR and AAS spectroscopy devices.

-Interpret UV, IR, MS, NMR and AAS spectrums for identification of organic compounds.

Statistical Design and Analysis of Experiments

This unit deals with the process design and experiment, using the basic statistics and statistical software. The process optimization, design and hypothesis of the experimental variables are covered in this unit.

Learning Outcomes

At the end of the course, the students must be able to:

-Understand the concepts related to sampling and population.

-Hypothesize the nature of research and experiments.

-Calculate and design the objective conclusion of data collected.

-Practice and demonstrate the research and experiment using statistics and statistical software.

-Verify the process design and process optimization.

-Relate the statistics in validation of research data.

-Manipulate the research skills using the statistical tool.